Item NO.:

Size request by userProduct Orgin:

ChinaBrand:

SanShineShipping Port:

XIAMEN,CHINAColor:

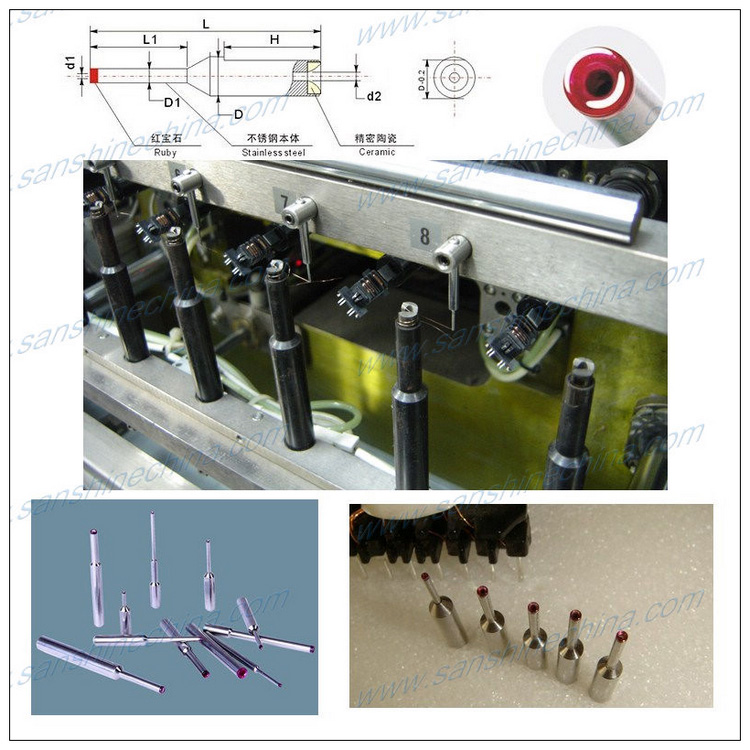

White and RedProduct name : Ruby tipped enamelled wire guide coil winding nozzle

Description:

This ruby tipped enamelled wire guide coil winding nozzle is used for guiding the fine enamelled copper wire to wind on the bobbion. This ruby tipped enamelled wire guide coil winding nozzle be fixed on the winding machine for guiding the wire to wind in orderly during the high speed winding. The ruby tipped enamelled wire guide coil winding nozzle is named fine enamelled wire winding nozzle also. This wire guide coil winding nozzle size by user request to make. This ruby tipped wire guide coil winding nozzle can guide wire and protect the insulation film of the fine enamelled copper wire during the high speed winding.

Features:

1. High Wear Resistance

This is assured by the choice of materials for wear elements possessing. Hardness Value: 1800 ~ 2200 Vickers, or 3times that of case hardened steel. Body material is stainless steel for structural supports, not wear-bearing.

2. Scratch-Proofing

Eliminate wire insulation film damage, low friction resistance, stable wire tension. The wire-guiding surfaces are mirror finished by diamond lapping to a surface roughness of 2 -4 micro inches Ra or better, material permit.

3. Straightness and Stiffness

Straightness and Stiffness are defined by the wire exit being concentric and inflexible with respect to the nozzle locating? . In plain terms, the wire should exit from the nozzle concentric to the locating? To within 0.02 mm, with or without load. A geometric characteristic presentation is shown at upper left. Concentricity to within 0.01mm.

4. Precise Exit Radii

Because the coil winding nozzle's Exit Radii governs the angle of the wire exit from one coil to the next, it should be monitored to + / - 0.025 mm. This is done by digital measurement, shown at upper right.

Specification:

Measurements are customized available by requested, outside diameter is governed by nozzle wall thickness. See the measurements drawing to confirm your nozzles measurements according to your winding machine and coil products.

Processing limit: d1≥0.2mm, D1≥0.7mm.

Can't find the specific information you're looking for? Have a question ? Contact Us

The mirror surface tungsten carbide motor coil winding nozzle is used in coil winding machines to protect the enamel insulation film of copper wire and guide the wire to wind on the stator and rotor, on the bobbin, on the pins for winding motors, generators.

The mirror surface tungsten carbide wire guide coil winding nozzle is used in the coil winding machines to protect the enamelled insulation film of the copper wire and guide the wire to wind the coil, wind wire on the pins of the bobbin for the manufacture of coils.

The front four spindles automatic coil winding machine (SS864) is used for winding the transformer, inductor, relay, contactor, choke, ignition coils, etc. . This winding machine be called four spindles contactor winding machine, four spindles filtering choke coil winding machine and four spindles lamination transformer winding machine also.

This Transformer motor generator varnish vacuum pressure impregnation machine (SS-V01) is used for impregnation and dipping the insulation varnish, insulation paint, insulation enamel, insulation resin, insulation enamel into the coil of transformers, relays, motors, inductors, etc. under the high vacuum status so that make sure the high insulation1

The standing floor type lead free soldering pot (SS-TG01) solder pot is conforming to RoHS Standards. This solder dipping equipment is used for soldering (tinning) the big electronics components and electical components, like as: transformers, relays, motors, valve coils, capacitors, inductors, cables, etc. . This solering pot is called floor stand1

The automatic transformer core EI sheet lamination machine (SS-ALEIXXX seires) is one PLC contorlling EI sheet inserting machine. The SS-ALEIXXX seires EI silicon sheet lamination machines model number and size is different and made according to the EI sheet size. This EI sheet stacking machine is used for inserting the silicon steel sheets into th1

The programable semiautomatic plastic string rewinding machine (SS-RW03) is one digital wire rewinding machine. This wire rewinding machine is used for winding the PVC or Nylon string to be one small coil from one big spool within a lot of wire. This machine is named plastic wire rewinder also.

online service

online service

+86-5926603065

lijiyi@windingmachinechina.com

sales@sanshinechina.com

sanshineelectronics

008613860450316

KEYYEELEE

008613860450316

673469847

KEYYEE66