Item NO.:

Size by user requestProduct Orgin:

ChinaBrand:

SanShineShipping Port:

XIAMEN,CHINAColor:

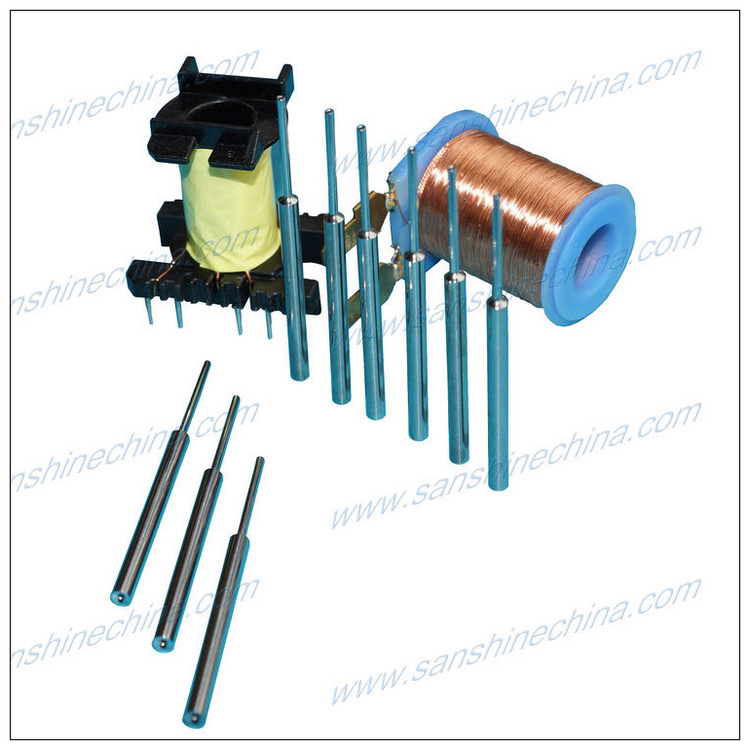

WhiteProduct name : Mirror surface tungsten carbide wire guide coil winding nozzle

Description :

The mirror surface tungsten carbide wire guide coil winding nozzle is used in coil winding machines to protect the enamelled inuslation film of the copper wire and guide the wire to wind on the bobbin and on the pins for the manufacture of coils, motors, transformers, relays, contactor, inductor and sensors in automotive, telecoms, electric and electronic applications. This tungsten carbide wire guide coil winding nozzle is called tungsten electromagnetism coil winding nozzle also. Also we use tungsten carbide to make the tungsten carbide blasting nozzles, tungsten carbide spray nozzles according to dimensions drawing.

Features :

1.High Wear Resistance

This is assured by the choice of materials for wear elements possessing a minimum hardness in excess of Vickers 1,000 (HRC 70).

2.Scratch-Proofing

Eliminate wire insulation film damage, low friction resistance, stable wire tension. the wire-guiding surfaces are mirror finished by diamond lapping to a surface roughness of 2 – 4 micro inches Ra or better, material permit.

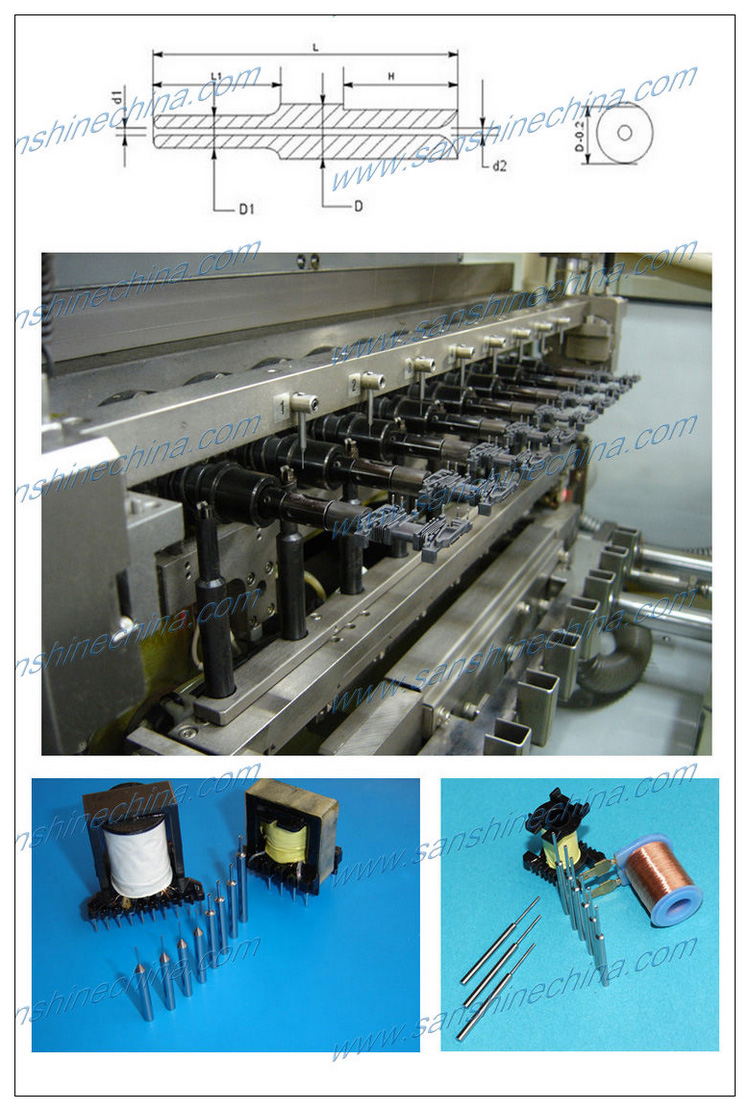

3.Straightness and Stiffness

Straightness and Stiffness are defined by the wire exit being concentric and inflexible with respect to the nozzle locating ?. In plain terms, the wire should exit from the nozzle concentric to the locating ? to within 0.02 mm, with or without load. A geometric characteristic presentation is shown at upper left. Concentricity to within 0.01mm.

4.Precise Exit Radii

Because the coil winding nozzle's Exit Radii governs the angle of the wire exit from one coil to the next, it should be monitored to + / - 0.025 mm. This is done by digital measurement, shown at upper right.

Specification :

Be made according to dimensions drawing, please refer the drawing picture.

Measurements :

Customize available by requested in dimensions drawing, outside diameter is governed by nozzle wall thickness. see the measurements drawing to confirm your nozzles measurements according to your winding machine and coil products or your nozzle samples.

prev :

Ruby tipped enamelled wire guide coil winding nozzleNext :

Mirror surface tungsten carbide motor coil winding nozzleCan't find the specific information you're looking for? Have a question ? Contact Us

The mirror surface tungsten carbide motor coil winding nozzle is used in coil winding machines to protect the enamel insulation film of copper wire and guide the wire to wind on the stator and rotor, on the bobbin, on the pins for winding motors, generators.

This ruby tipped enamelled wire guide coil winding nozzle is used for guiding the fine enamelled copper wire to wind on the bobbion.

The two axes programmable linear coil winding machine controller (SS200LWC) is a precise digital type programmable linear coil winding machine controlling system. This controller can drive the DC brush winding spindle motor, DC brushless winding spindle winding motor and wire spreading step motor directly without connect the external motor dri1

The automatic high torsion thick wire coil winding machine (SS851) is a CNC programmable winding machine with the high torsion DC winding motor. It's the best choice for secondary winding of transformer, reactive coil, electric power transformer and big coil of thick wire. This winder be named CNC start transformer winding machine also.

The ACDC high voltage withstand insulation resistance hipot tester (SS7122) is used for testing insulation grade and withstanding voltage capability of electrical equiment, electric devices and electronics components.

This amorphous ribbon big size range toroidal core automatic welding winding machine adopts precise programmable PLC winding controller. It's an accurately and reliability programmable amorphous ribbon toroidal core winding machine with welding function. This ribbon toroid core winding equipment is named nanocrystalline magnetic toroidal core winde1

The 6 Inch slider type automatic toroid coil winding machine (SS900S6, 6 inch winding head) is used for winding the fine wire coils on the toroidal core(about core OD 60mm). like as toroid transformers, toroid inductors and so on. This toroid coil winding machine (SS900S6) is named micro metal toroid core winding machine also.

The front two spindles automatic coil winding machine (SS862) is used for winding the fine wire coils. Like as : transformers, inductors, relays, contactor, etc. . This winding machine also be called contactor coil winding machine.

online service

online service

+86-5926603065

lijiyi@windingmachinechina.com

sales@sanshinechina.com

sanshineelectronics

008613860450316

KEYYEELEE

008613860450316

673469847

KEYYEE66