Item NO.:

SS-GR04Product Orgin:

ChinaBrand:

SanShineShipping Port:

XIAMEN,CHINAColor:

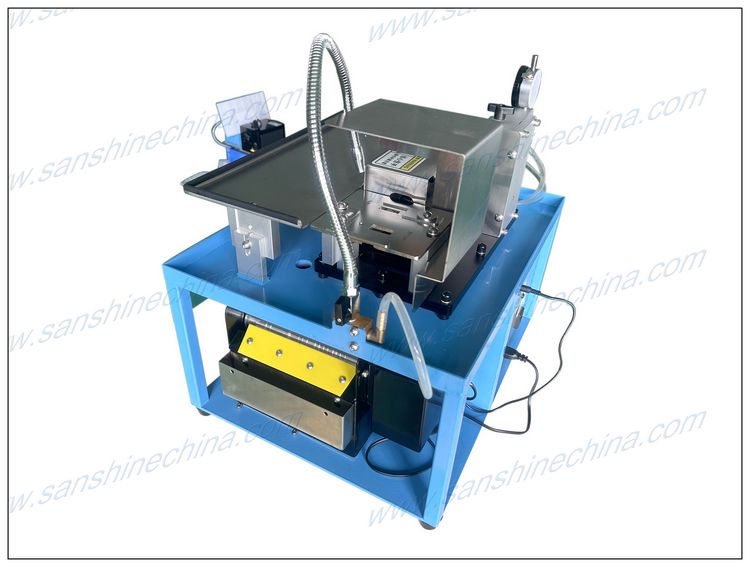

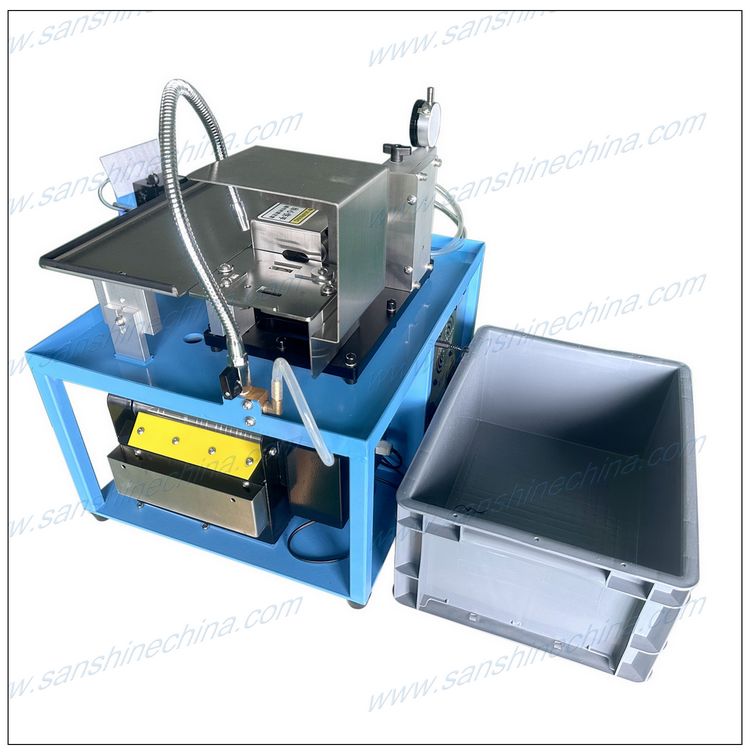

Blue and blackProduct name : Small ferrite core air gap water type grinding machine (SS-GR04):

Description of Small ferrite core air gap water type grinding machine (SS-GR04):

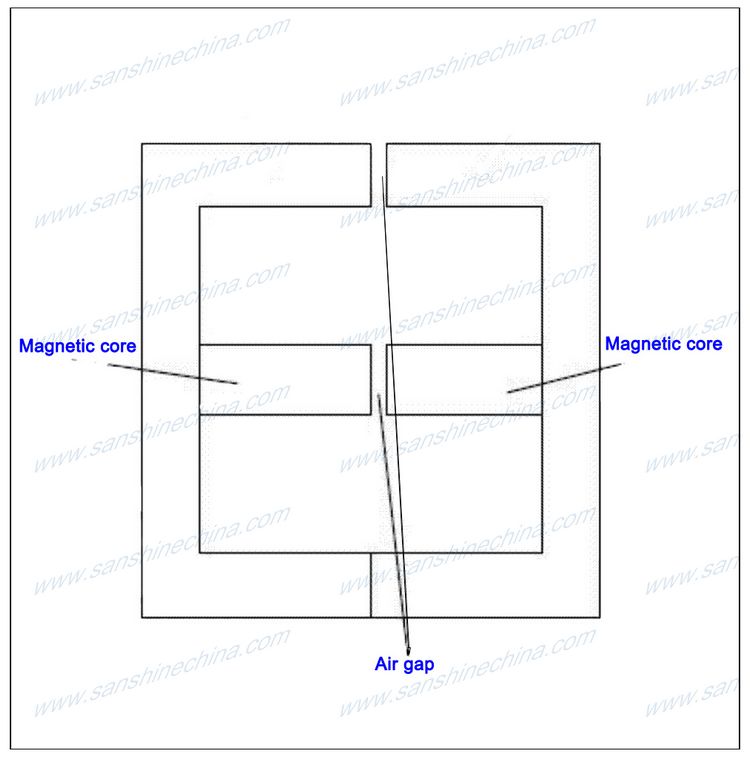

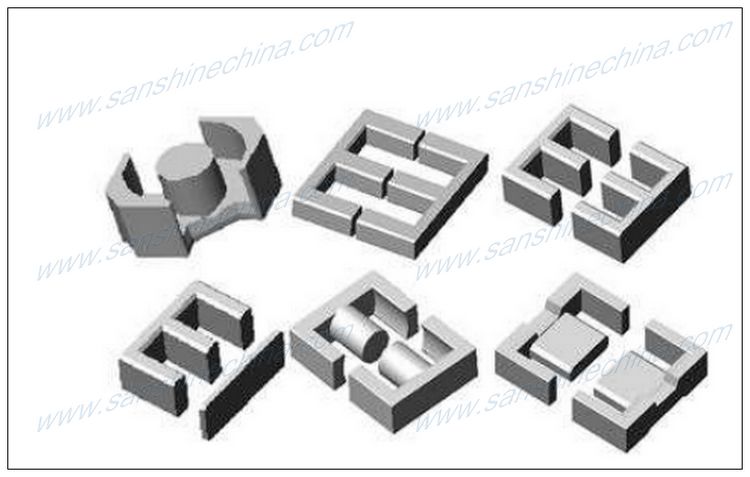

This small ferrite core air gap water type grinding machine (SS-GR04) is used for grinding the air gap of small ferrite cores of transformer and inductor.

Like as the EE and ER and PQ series cores. It adopts water to clean the core during grinding processing. This machine adopts the water cooling type 1.5KW

grinding motor. This grinding machine is called transformer EE core gap grinding machine also. The machine is only suited for the engineering RD room or

production line of the small output quantity. It is one manual machine.

Feature of Small ferrite core air gap water type grinding machine (SS-GR04):

|

Grinding way |

Manually holding core one by one |

|

Grinding depth of the core |

≤4.5mm. |

|

Griding air gap accuracy |

0.01~0.03mm |

|

Grinding wheel width |

6mm or 12mm |

|

Motor power |

water cooling type DC brushless 1.5KW |

|

Water pump |

DC 12V |

|

Machine net weight |

47Kgs |

|

Machine size |

L520*W420*Height 450mm |

|

Machine power source |

Single phase AC220V ,50 /60Hz |

|

Grinding wheel speed |

Adjustable Max. 24000RPM. |

|

The height of grinding wheel |

Adjustable and display with dial indicator |

|

Motor working limited time |

Continually. |

Can't find the specific information you're looking for? Have a question ? Contact Us

This small ferrite core air gap grinding machine (SS-GR02) is used for grinding the air gap of small ferrite cores of transformer and inductor. This grinding equipment is called inductor core gap grinding machine also.

This small ferrite core air gap water type grinding machine (SS-GR03) is used for grinding the air gap of small ferrite cores of transformer and inductor. This grinding machine is named inductor core gap grinding equipment also.

This amorphous ribbon big size range toroidal core automatic welding winding machine adopts precise programmable PLC winding controller. It's an accurately and reliability programmable amorphous ribbon toroidal core winding machine with welding function. This ribbon toroid core winding equipment is named nanocrystalline magnetic toroidal core winde1

The 200KHZ automatic judgement precise digital LCZ LCR meter (SS1062) is for used for testing the passive components.

These automatic adhesive tape cutting dispensing machines are used for cutting and feeding the tape, adhesive tape, protective film, thermal shrinkage bushing(tube, harnees, sleeve) in measured precision automatically, the machine is according to user required length to cut and dispense fast in precision automatically.

The two axes programmable linear coil winding machine controller (SS200LWC) is a precise digital type programmable linear coil winding machine controlling system. This controller can drive the DC brush winding spindle motor, DC brushless winding spindle winding motor and wire spreading step motor directly without connect the external motor dri1

The high frequency transformer parameters automatic analyzer (SS3252) is a precise testing system which designed for transformer RD and production lines or incoming and outgoing inspection in quality control process with high stability and high reliability.

This small ferrite core air gap water type grinding machine (SS-GR03) is used for grinding the air gap of small ferrite cores of transformer and inductor. This grinding machine is named inductor core gap grinding equipment also.

online service

online service

+86-5926603065

lijiyi@windingmachinechina.com

sales@sanshinechina.com

sanshineelectronics

008613860450316

KEYYEELEE

008613860450316

673469847

KEYYEE66